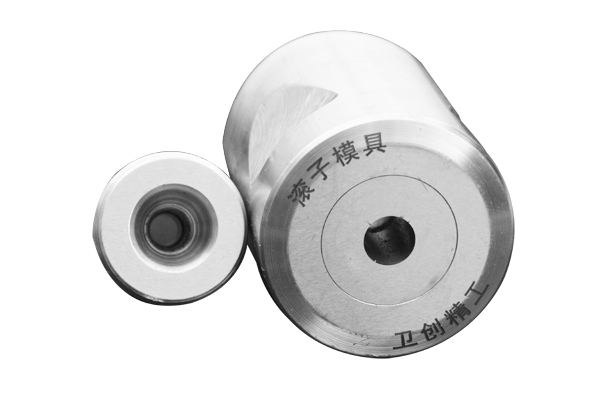

Wire draw dies

WBM wire draw dies use crystal diamond,long lifetime.

The wire drawing die is an important tool for metal wire drawing processing. Its advantages include:

1.High precision: The wire drawing die can provide high-precision processing to ensure that the size and surface quality of the final product meet the requirements.

2.Wear resistance: High-quality wire drawing dies are usually made of wear-resistant materials and can withstand long-term high-intensity use without failure.

3.High efficiency: The wire drawing die can achieve high-efficiency production, can quickly process a large amount of metal materials, and improve production efficiency.

4.Flexibility: The wire drawing die can be adjusted and replaced as needed, and is suitable for processing metal materials of different diameters and shapes.

5.Cost-effectiveness: Compared with other processing methods, wire drawing molds have lower costs and can achieve return on investment in a shorter time.

Information

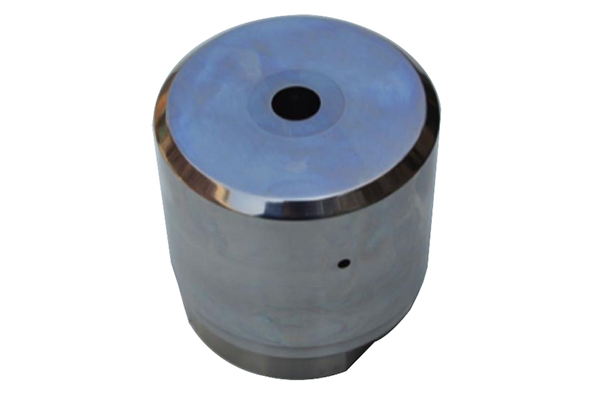

Quill

WBM produces taper roller dies with high efficiency and automation. Rollers are formed on a single automatic cold heading press and are fed, cut, and punched into the die for five steps.

We can produce different types and sizes taper roller dies with quality assurance,include:Combination Punch,Outside Sleeve,Blade,Combination Punch,Feed Cylinder,Combination Dies,Double Layer Sleeve,Insert.

Information

Heading dies,Punch

WBM produces taper roller dies with high efficiency and automation. Rollers are formed on a single automatic cold heading press and are fed, cut, and punched into the die for five steps.

We can produce different types and sizes taper roller dies with quality assurance,include:Combination Punch,Outside Sleeve,Blade,Combination Punch,Feed Cylinder,Combination Dies,Double Layer Sleeve,Insert.

Information

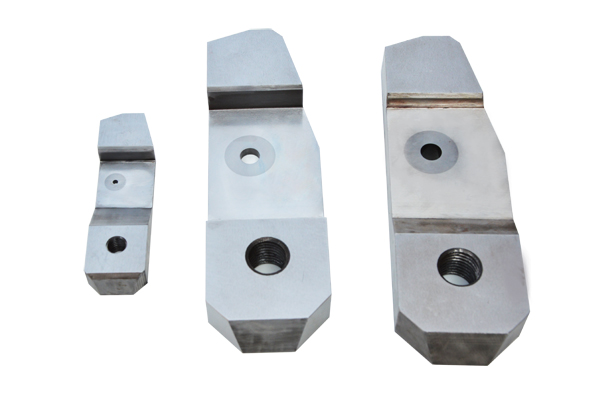

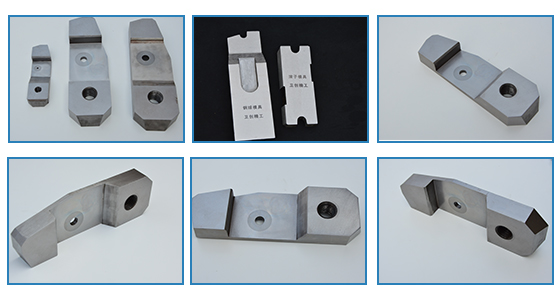

Cutter

WBM produces taper roller dies with high efficiency and automation. Rollers are formed on a single automatic cold heading press and are fed, cut, and punched into the die for five steps.

We can produce different types and sizes taper roller dies with quality assurance,include:Combination Punch,Outside Sleeve,Blade,Combination Punch,Feed Cylinder,Combination Dies,Double Layer Sleeve,Insert.

Information

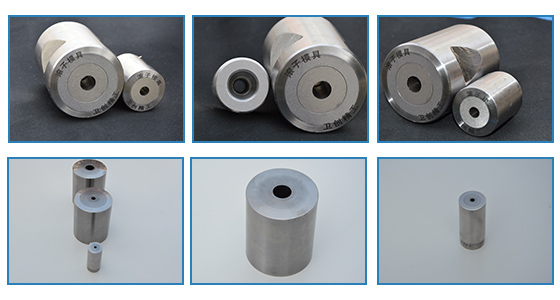

Taper dies

WBM produces taper roller dies with high efficiency and automation. Rollers are formed on a single automatic cold heading press and are fed, cut, and punched into the die for five steps.

We can produce different types and sizes taper roller dies with quality assurance,include:Combination Punch,Outside Sleeve,Blade,Combination Punch,Feed Cylinder,Combination Dies,Double Layer Sleeve,Insert.

Information

Punch pin,Push out pins

WBM produces taper roller dies with high efficiency and automation. Rollers are formed on a single automatic cold heading press and are fed, cut, and punched into the die for five steps.

We can produce different types and sizes taper roller dies with quality assurance,include:Combination Punch,Outside Sleeve,Blade,Combination Punch,Feed Cylinder,Combination Dies,Double Layer Sleeve,Insert.

Information